Absolute bearing vibrations

Guide bearings task is to ensure stable dynamic and static behaviour of the rotor in all operating conditions. Therefore monitoring the forces applied on bearing through the oil film is very important for bearing health tracking. Bearing stiffness, support and seals can deteriorate in exploitation. This measurements are best suited in combination with Relative Shaft vibrations.

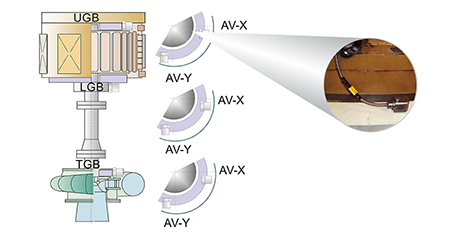

Absolute bearing Vibration measurements are conducted using accelerometers or velocity meters positioned in two perpendicular directions.

On thrust bearings sensors can be placed in axial direction to monitor the load on axial bearing.

Faults and conditions detected

Rotor dynamics problems (mechanical, electrical, hydraulic unballance)

Bearing stiffness problems

Bearing support problems

Shaft to bearing rub

Typical configuration

2 accelerometers or velocity meters in perpendicular direction in each guide bearing planes (typically 4-10 sensors per unit)

CoDiS RT – on-line monitoring and protection instrument

CoDiS RT – on-line monitoring and protection instrument

CoDiS DM – on-line and off-line diagnostic software

Sensors

- Piezo electric sensors

On-line Instrument

- CoDiS RT - Real time Protection unit

Diagnostic Modules

- CoDiS DM - Diagnostic Monitoring

download

- VMS02